09 OCT 2025

For decades, natural gas was considered the cleanest fossil fuel. But today, the demands of decarbonization and the need for more flexible energy sources are driving a deeper transformation: one that redefines the origin of the gas itself. In this context, biomethane —also known as Renewable Natural Gas (RNG)— is emerging as one of the most effective, scalable, and mature solutions for the energy transition.

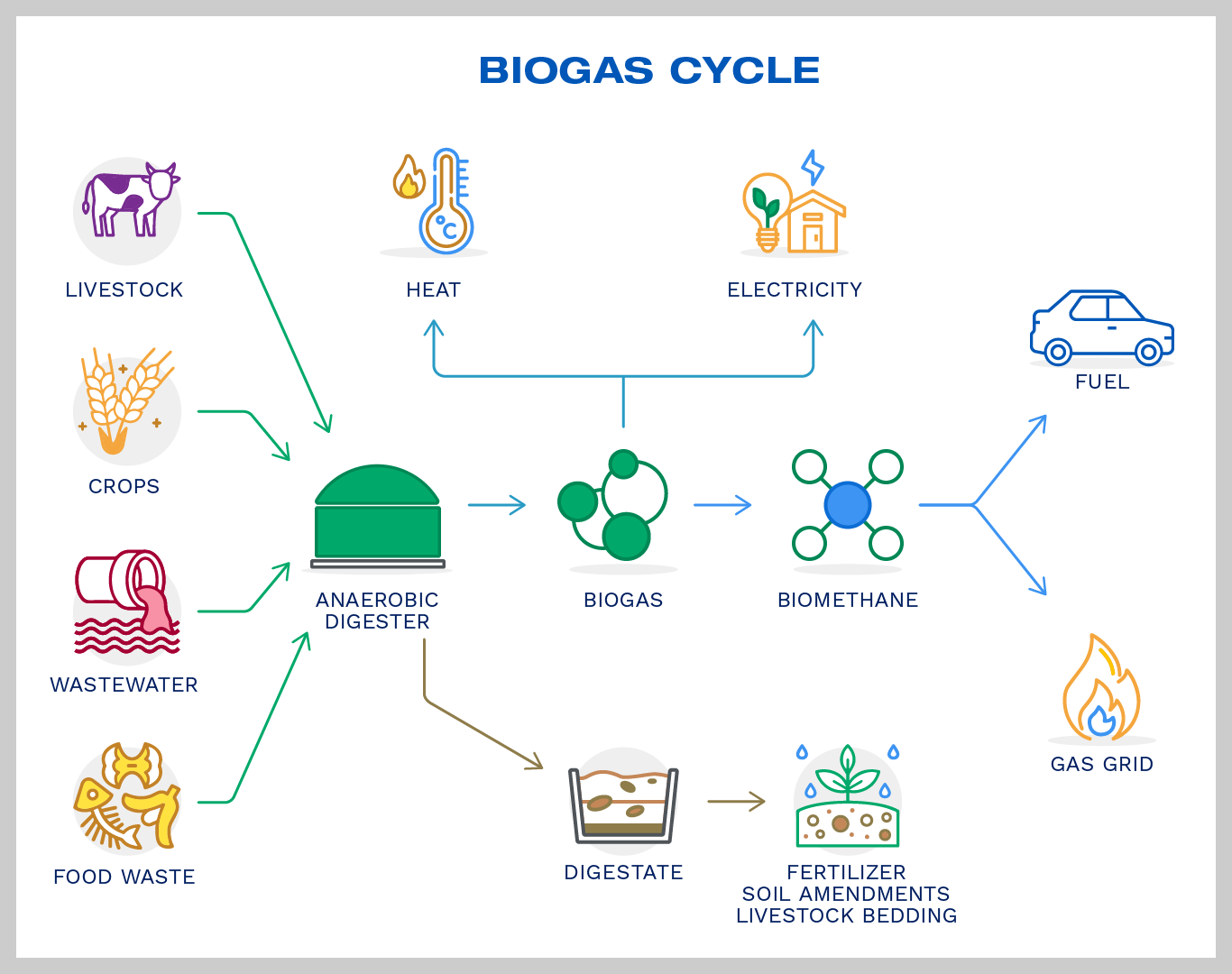

Biomethane is produced from organic waste: manure, crop residues, wastewater, food scraps, or industrial by-products. Through anaerobic digestion and purification processes, a gas with a composition similar to fossil natural gas —methane (CH₄)— is obtained. This makes it compatible with existing networks, engines, boilers, and plants, without the need for infrastructure modification.

The difference lies in its origin. While fossil gas adds new carbon to the atmosphere, biomethane harnesses the energy contained in organic residues that, if untreated, would release methane and CO₂ during natural decomposition. In some cases, it can even achieve a negative carbon balance, by preventing uncontrolled decomposition that would otherwise emit greenhouse gases.

But its true potential lies in its versatility and decentralization. Biomethane can be produced and consumed locally —in rural or urban settings, at small or large scale— and adapted for uses as diverse as heavy transport, power generation, or grid injection.

In a global context where countries are seeking real alternatives to fossil gas, organic waste is accumulating without productive use, and energy systems demand flexible solutions, biomethane is no longer a promise. It’s already in operation —and ready to scale.

Rural Opportunities: Energy That Already Exists

From Manure to CNG: The Potential of Agriculture

Much of the world’s biogas originates on farms. Manure, crop residues, vinasse from sugarcane, dairy effluents, or livestock waste —these are abundant resources that, when unmanaged, become environmental liabilities. But when properly harnessed, they can be transformed into clean, local, and continuous energy.

In countries with strong agricultural activity —such as the United States, Brazil, Argentina, India, or Germany— the potential is enormous. In the U.S. alone, the EPA estimates over 8,000 sites suitable for anaerobic digestion, many already operating. In Brazil, the RenovaBio program and CBIOs certificates incentivize projects converting vinasse into biomethane for vehicle or industrial use. In Argentina, with a high concentration of cattle in feedlots and dairies, a significant portion of rural diesel demand could be replaced by Bio-CNG produced on-site.

Such projects are viable thanks to modular production technologies that enable biogas capture, purification, and compression directly at the source. Solutions like Galileo Technologies’ Biobox® series are specifically designed for these rural and agro-industrial environments —from dairies to sugarcane plants.

When There’s No Pipeline

Rural biomethane doesn’t have to wait for a gas pipeline. Thanks to modular and mobile solutions, it can be captured, purified, compressed, or even liquefied on-site, and then transported by truck to where it’s needed —fuel stations, industrial facilities, or local grids.

In rural environments where access to infrastructure is limited, integrated systems simplify deployment. Galileo’s Biobox line combines upgrading and compression in a single transportable unit operating at low pressure. These units process 200 to 1,500 Nm³/h of biogas, making them suitable for small to mid-scale installations such as dairies, agro-industrial plants, or landfills. Biobox Low Pressure (LP) models deliver biomethane at pressures below 250 barg, while Biobox High Pressure (HP) units generate Bio-CNG at full pressure, ready for truck loading or direct use in local applications.

Such solutions enable virtual pipeline models, already used worldwide to move renewable gas from the production site to the point of consumption. On-site consumption is also common —for example, in farm fleets, tractors, or irrigation systems currently powered by diesel. In many cases, the biomethane produced can meet 100% of a facility’s energy demand.

Practical Applications: Transport, Industry, Power

The most widespread applications of rural biomethane include:

- Agro-industrial transport (replacing diesel in fleet operations)

- Local industries (boilers, dryers, thermal processes)

- Power generation with dual-fuel or 100% methane engines

Real-World Cases: From Field to Energy

In the U.S., farms such as Liberty RNG in Wisconsin convert cattle manure into compressed biomethane used as renewable fuel for trucks. In Brazil, Adecoagro produces Bio-CNG from sugarcane vinasse —a liquid residue— replacing diesel in its internal fleet. Across Argentina, dairies and feedlots are exploring similar self-supply models.

Urban Opportunities: Biomethane from Waste

Energy in Waste

Worldwide, cities face the same challenge: what to do with their waste. Overloaded landfills, food waste, wastewater —when mismanaged, these materials emit greenhouse gases, especially methane.

Yet these same residues can become a renewable, dispatchable energy source. Compact upgrading modules, such as Galileo Technologies’ amine systems, allow these projects to be implemented at landfills or transfer stations without major civil works.

What If Treatment Plants Produced Their Own Energy?

Across cities from California to Stockholm, wastewater treatment plants are capturing and upgrading their biogas for self-consumption or grid injection.

Companies like AB Energy in Europe have developed integrated digestion and cogeneration systems, while others —such as Galileo Technologies— provide modular upgrading and compression units that transform this biogas into biomethane ready for use or injection.

Case Study: Puerto Rico Turns Waste into Energy

At the El Coquí landfill in Puerto Rico, captured gas is upgraded into biomethane to power a local generation plant. Modular upgrading and compression solutions enabled a rapid startup without large-scale civil works.

What’s Needed to Accelerate Deployment

Incentives to Level the Playing Field

Biomethane competes with a fossil fuel backed by decades of infrastructure and subsidies. To give this renewable alternative a fair chance, clear and stable policy frameworks are essential.

The U.S. has programs like the Renewable Fuel Standard (RFS) and Low Carbon Fuel Standard (LCFS) in California, granting credits per ton of CO₂ avoided. Brazil follows with RenovaBio and CBIOs, rewarding verified emission reductions. In Europe, renewable gas quotas and Guarantees of Origin drive adoption.

Upgrading: The Technical Key to Gas Quality

To transform biogas into commercial-grade biomethane, it’s not enough to remove CO₂ —other compounds like H₂S, siloxanes, VOCs, and moisture must also be eliminated to ensure purity and prevent corrosion.

The most common technologies include amine scrubbing, membrane separation, and pressure swing adsorption (PSA) —each with specific trade-offs in energy efficiency, reagent use, flow variability, and footprint.

For projects handling biogas with variable composition, amine systems are often the most effective. Galileo Technologies has developed compact amine modules capable of removing CO₂, H₂S, and VOCs with high efficiency, without water or corrosive reagents. Their closed-loop design with thermal regeneration enables continuous operation at low OPEX, even in remote sites or limited-infrastructure environments.

Transport, Compression, and Storage: Thinking Systemically

Producing biomethane is only the beginning. To reach consumers, it must be compressed, stored, and transported efficiently. Solutions include Bio-CNG filling stations, regasification systems, Bio-LNG isocontainers, and virtual pipelines that deliver gas where no pipelines exist.

Smart logistics design can turn rural or urban waste into accessible energy for fleets, industries, and cities.

When the destination requires liquefaction or grid injection, gas purity must exceed 99%, free of CO₂ and moisture. Galileo Technologies’ ZPTS® molecular sieve plant ensures less than 50 ppm CO₂ and H₂O, and can be integrated with Cryobox® liquefaction units to produce Bio-LNG on-site, enabling distribution via isocontainers —opening new supply routes for off-grid markets..

The Opportunity Is Everywhere

Biomethane is not a promise —nor an experiment. It’s a proven, real-world solution operating across the globe: on farms, in landfills, dairies, wastewater plants, and sugarcane mills —wherever waste is turned into energy.

Its value lies not only in its renewable origin but in its adaptability —to diverse geographies, scales, and applications. It can be injected into grids, used in transport, stored as Bio-LNG, or consumed locally.

What enables deployment is a combination of modular technology, decentralized energy models, and regulatory frameworks that recognize its environmental and strategic value.

Every country, region, and energy stakeholder stands to benefit. The only thing missing is the will —and decision— to scale what already works. Because biomethane isn’t the future of gas. It’s its evolution.

Sources & References

-

U.S. EPA AgStar Program – Market Opportunities for Biogas Recovery Systems.

-

Mobility Foresights: Latin America Biomethane Market Report.

-

MDPI – Biomethane and BioGNL as Future Fuels in the Circular Economy.

-

Grand View Research: Biomethane Market Outlook – Argentina / Brasil / USA